Custom Switching Transformer Manufacturer

Altran engineers high-reliability, custom switching transformers tailored to your exact specifications. Every unit is built at our manufacturing facility in the United States. We partner with OEMs to deliver optimized magnetic solutions that maximize performance and efficiency for demanding power electronics applications.

Made In the U.S.A. Custom Switching Transformers

At Altran, we specialize in designing and building custom power transformers tailored to specific voltage, At Altran, we are a custom switching transformer manufacturer that produces high-quality transformers operating at high frequencies for power electronics applications. We draw on four decades of production experience to select optimized core materials and use precision windings that maximize efficiency. Every transformer is produced at our CSA, UL, and CE-certified manufacturing facility in Crystal Lake, Illinois.

Domestic production eliminates international shipping delays and provides direct communication channels between your engineering team and our manufacturing specialists. Supply chain disruptions become manageable through local sourcing of materials and components rather than dependence on overseas logistics networks. Quality control issues receive immediate attention and resolution without the complications of time zone differences or language barriers that can extend problem-solving cycles for weeks.

What Are Switching Transformers?

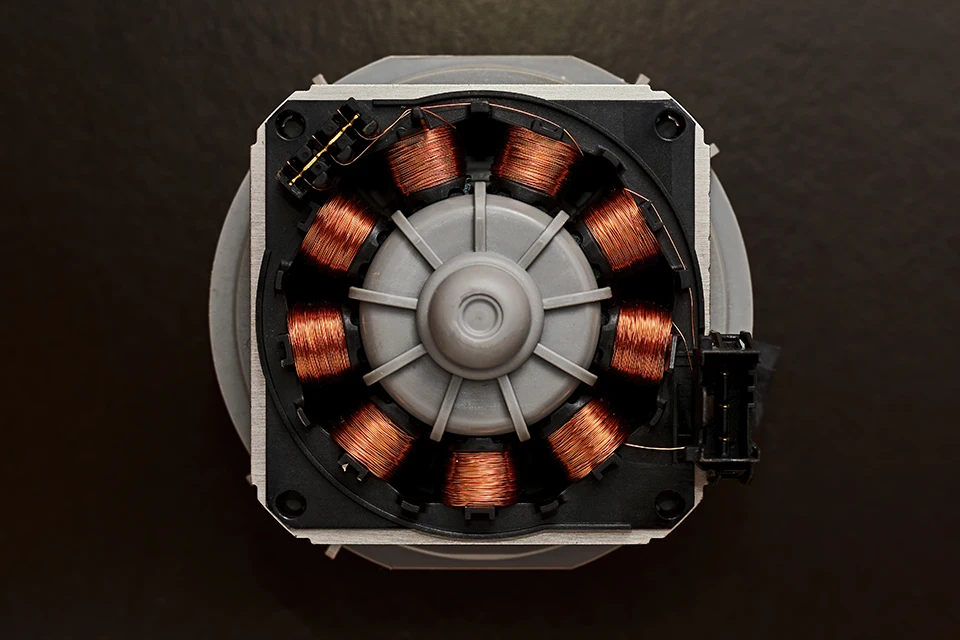

A switching transformer, also known as a switch-mode transformer, is a primary component inside a switched-mode power supply. It transfers electrical energy and converts voltage and current levels for the circuit. These devices are integral to the function of countless modern electronic systems.

Switching transformers also provides galvanic isolation by creating an electrical separation between the input and output circuits of the power supply. Galvanic isolation is a critical safety feature that protects end-users from hazardous voltages. It also breaks ground loops, which reduces unwanted electrical noise in sensitive electronics.They operate using high-frequency alternating current, often above 20 kilohertz. Conversely, traditional transformers use the low-frequency power available from a standard wall outlet. The high-frequency method enables the creation of smaller, lighter, and more efficient power conversion products.

Switching Transformer Research & Development Capabilities

Altran is a custom switching transformer manufacturer that specializes in custom-designed switch-mode transformers that are optimized for performance in high-frequency switching environments, such as flyback, forward, push-pull, half-bridge, and full-bridge topologies.

Our engineering team builds each transformer to meet specific electrical, thermal, safety, and dimensional requirements. From small signal transformers to high-isolation converters, we support a wide range of technical configurations:

Supported Core Geometries

- E-Core / EC-Core

- RM-Core / PQ-Core

- Pot Core / U-Core

- Toroidal

- Custom Low-Profile

- Fully Custom Geometries (Designed & Fabricated In-House)

Design Capabilities

- Frequencies from 20 kHz to 1 MHz+

- Power levels from milliwatts to kilowatts

- Multi-winding and tapped configurations

- Primary-to-secondary isolation up to 10 kV

- Surface-mount or through-hole formats

- Low leakage inductance and tight coupling

- Custom Designs

Customers and Industries We Serve

Altran provides switching transformers to a wide range of OEMs and technology developers across many different industries, including:

- Power Supply Manufacturers

- Industrial Automation OEMs

- EV Charger and Battery System Integrators

- Defense Contractors

- Telecom and Networking Equipment Providers

- Renewable Energy Equipment Makers

- Embedded System and IoT Device Developers

- Medical Device Manufacturers (non-patient contact)

- High-Reliability Research & Development Teams

Industries We Work With

We design and manufacture custom switching transformers for a broad range of high-performance applications:

- Power Supplies (AC-DC & DC-DC)

- EV Chargers and Battery Management

- Telecommunications & Networking

- Industrial Automation & Control Systems

- Renewable Energy Systems

- Consumer and Professional Electronics

- Defense

- Medical Electronics (Low-Voltage, Non-Patient Contact)

Custom-Only Solutions

Altran produces transformers exclusively for individual client applications. Each project begins with your specific requirements since we stock no pre-manufactured units or standard models in our facility.

Our team integrates directly into your development process to define exact specifications and performance targets. This hands-on collaboration produces transformers that operate precisely within your technical parameters while satisfying regulatory requirements.

How to Specify a Custom Switching Transformer

Our engineers work closely with your team to define the technical and operational needs of your application. Providing detailed specifications ensures the final component meets your performance, safety, and integration targets.

Here is some additional info of design information needed:

Electrical Requirements

- Input voltage range (e.g., 85–265 VAC rectified → 120–375 VDC).

- Output voltages and currents (number of rails, regulation class).

- Topology (flyback, forward, push-pull, half-bridge, full-bridge, LLC resonant, etc.) — defines whether the transformer stores energy or mainly transfers it.

- Turns ratio based on duty cycle, topology, and target voltage.

- Isolation voltage rating (hipot test value, e.g., 3 kV–5 kV RMS).

- Leakage inductance target (too high → poor regulation; too low → may break ZVS/ZCS operation in resonant topologies).

Magnetic Requirements

- Core material chosen for operating frequency (ferrite for 20 kHz–500 kHz, nanocrystalline/amorphous for higher power).

- Core shape (EE, ETD, PQ, RM, planar, toroid) depending on power density and manufacturability.

- Flux density limit (ΔB) set to avoid saturation at peak current (often ≤0.2–0.3 T for ferrites).

- Magnetizing inductance (Lm) is defined to set the current slope and ensure proper reset (forward) or storage (flyback).

- Gap requirements (e.g., flyback transformers use an intentional gap to store energy).

Thermal Requirements

- Copper loss (I²R) in windings due to DC and AC resistance (skin and proximity effects matter at high frequency).

- Core loss calculated with Steinmetz parameters at switching frequency and flux swing.

- Cooling method (convection, forced air, conduction).

- Max temperature rise allowed (e.g., ≤40 K over ambient, or per safety standard).

Mechanical & Safety Requirements

- Creepage and clearance distances between primary and secondary windings (per IEC/UL 62368, often 4–8 mm depending on working voltage).

- Insulation system (triple-insulated wire, tape layering, margin tape, or interleaving barriers).

- Winding layout for controlled leakage inductance and EMI performance.

- Package constraints (max height, footprint, pinout).

- Mounting style (through-hole bobbin, surface-mount planar, potted, etc.).

Regulatory/Performance Requirements

- Safety standards (UL, IEC, EN for creepage/clearance and dielectric strength).

- Efficiency targets (transformer losses must support overall SMPS efficiency).

- EMI considerations (stray capacitance between windings influences common-mode noise).

- Reliability targets (thermal cycling, insulation aging, moisture resistance).

Altran Custom Switching Transformers

Altran has over 40 years of experience designing and building custom transformers for demanding power electronics applications. Our manufacturing process ensures each component meets client specifications for performance and reliability. Click below to learn more and get a quote.