Custom Isolation Transformer Manufacturer

Altran manufactures custom isolation transformers built to meet the exact requirements of various applications. We produce each unit at our CSA, UL, and CE-certified facility in Crystal Lake, Illinois. Our engineering team works closely with clients from initial prototype development through full-scale production. This hands-on process ensures our designs match their electrical, mechanical, and performance requirements.

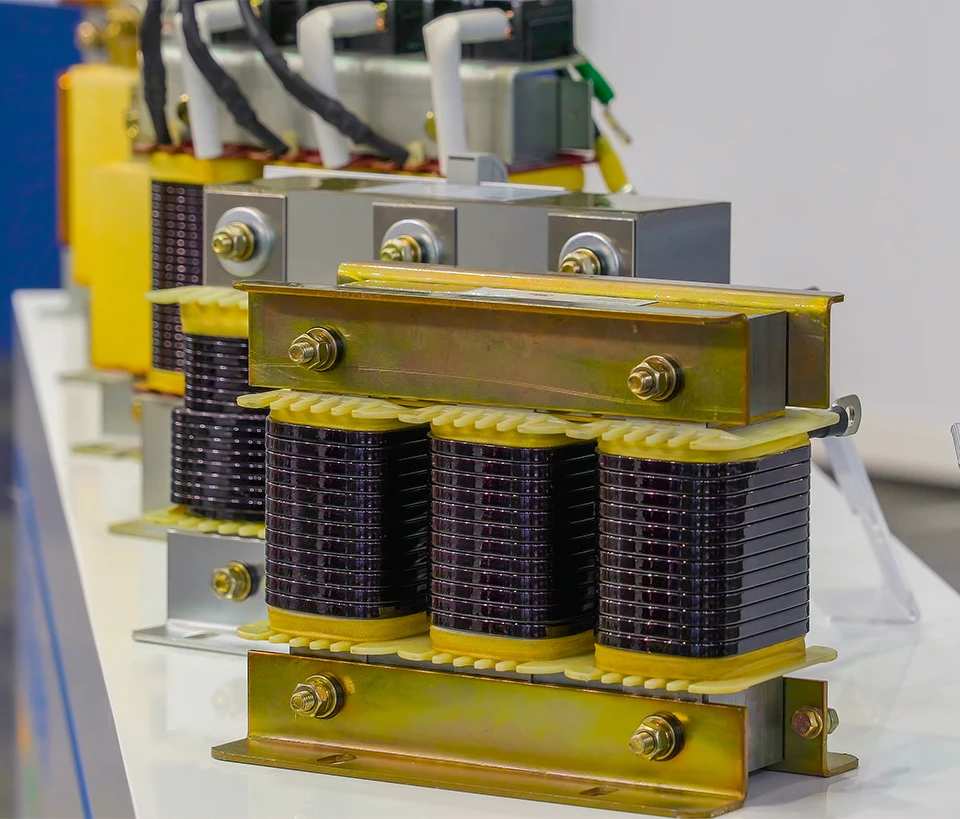

What Is an Isolation Transformer?

An isolation transformer transfers electrical energy from an AC source to a piece of equipment without a direct connection. It uses electromagnetic induction to move power between two physically separated circuits. The device’s primary and secondary windings wrap around a central ferromagnetic core to facilitate this process.

Many isolation transformers feature a 1:1 turns ratio between their primary and secondary windings. This specific design ensures the output voltage precisely matches the input voltage. The resulting galvanic isolation breaks the conductive path and protects users from dangerous ground faults.

Made In the U.S.A. Custom Isolation Transformers

Our Crystal Lake, Illinois, facility manages the entire production of each custom isolation transformer, from winding and encapsulation to final testing. The same location contains our engineering, purchasing, and quality departments. Colocating these teams improves operational feedback and protects intellectual property. The result is a consistent product that meets both strict client requirements and industry safety standards.

Altran technicians wind each coil from the first turn to final encapsulation. They use calibrated instruments to document electrical parameters at multiple production stages. Each finished unit then undergoes environmental stress testing that simulates demanding operational conditions. We only ship out after our QC department verifies that the transformer meets all performance and safety standards.

Custom-Only Solutions

Every isolation transformer we build is 100% custom — tailored from the ground up to meet your application’s electrical, mechanical, and compliance needs. Altran does not supply off-the-shelf isolation transformers.

We construct, test, and document each unit to meet specific customer requirements. Whether you need a compact medical-grade isolation transformer or a ruggedized industrial unit, our team will collaborate with you to develop a robust and reliable design.

Research & Development Isolation Transformer Capabilities

At Altran, we’re a custom isolation transformer manufacturer located in Illinois. We engineer and build our products to meet precise voltage, current, and environmental needs. Every unit we produce is designed for high efficiency and operational safety to ensure consistent performance and a long service life.

Our engineers specialize in custom-designed isolation transformers that are optimized for safety, galvanic isolation, and noise reduction. Galvanic isolation separates input and output circuits so no direct electrical current can flow between them. This provides:

- Operator safety is achieved by preventing hazardous voltages from passing through

- Noise suppression by breaking ground loops and reducing

- EMI Surge resilience by limiting transient transfer to sensitive electronics

- Functional separation between systems with different ground potentials

We offer the following supported core geometries:

- EI Laminations

- UI Laminations

- Toroidal

- Split Bobbin

- Custom Low-Profile

- Fully Custom Geometries (Designed & Fabricated In-House)

Design Capabilities

Altran engineers develop solutions that cover everything from compact low-power units to rugged high-capacity builds. Each transformer is crafted in-house to exacting standards and verified for long-lasting performance in tough conditions.

- Wide range of primary-to-secondary isolation voltages (per UL/IEC standards)

- Power levels from milliwatts to kilowatts

- Multi-winding and tapped configurations

- Controlled leakage inductance and interwinding capacitance for EMI performance

- Surface-mount or through-hole formats

- Encapsulated / epoxy-potted options for harsh environments

Material Selection for Application-Specific Performance

The performance and reliability of a custom isolation transformer are fundamentally determined by the materials used in its construction. Selecting the right combination of core, winding, and insulation materials is crucial for tailoring the unit to meet precise electrical, thermal, and mechanical demands.

The engineering processes we use carefully consider the interplay between different materials to achieve the desired performance characteristics:

High-Efficiency Power Conversion: To minimize energy loss in power supply applications, we select low-loss core materials like high-grade silicon steel or ferrites. This ensures maximum power transfer and reduces waste heat.

Low-Noise Medical & Audio: For sensitive medical or high-fidelity audio equipment, materials like copper foil for electrostatic shields are integrated between windings to minimize electromagnetic interference (EMI) and ensure signal purity.

Harsh Industrial Environments: In applications exposed to moisture, vibration, or chemicals, we utilize high-temperature insulation systems and epoxy encapsulation. These rugged materials protect the transformer’s windings and ensure long-term reliability under demanding operational stress.

Compact Aerospace & Defense: For applications where size and weight are critical, we utilize advanced materials like amorphous metal cores and foil windings. These materials enable the design of compact, lightweight transformers without compromising power handling or thermal performance.

High-Frequency Power Systems: In high-frequency switch-mode power supplies and telecom equipment, ferrite cores are selected for their superior performance and low-loss characteristics at higher operating frequencies. This choice is critical for maximizing efficiency and minimizing heat in compact electronic systems.

Stable Test & Measurement: For precision test and measurement equipment, we select core and winding materials with high thermal stability. This ensures the transformer’s electrical characteristics remain constant and predictable across the full operating temperature range, guaranteeing accurate and repeatable results.

Industries We Serve

We design and manufacture custom isolation transformers for a broad range of to a wide range of OEMs and technology developers across industries, including:

- Power Conversion, Line Isolation, and Power Supply Manufacturers

- Medical Device Manufacturers and Electronics ( non-patient contact)

- Telecom and Networking Equipment Providers

- Industrial Automation OEMs & Control Systems

- Renewable Energy Systems

- Test & Measurement Equipment Manufacturers

- Defense & Aerospace

- Consumer and Professional Electronics

- Embedded System and IoT Device Developers

- High-Reliability Research & Development Teams

Altran Custom Isolation Transformers

At Altran, we have over 40 years of experience in transformer design and manufacturing. We use this expertise to engineer custom solutions built for specific electrical, thermal, safety, and dimensional requirements. Click below to learn more and get a quote.