Custom Inductor Manufacturer

Altran manufactures high-quality, custom inductors to meet precise application requirements. Our engineers work closely with OEMs by designing each component to their specific electrical, mechanical, and thermal values. Every design is validated through rigorous testing protocols to ensure optimal performance and long-term reliability.

Made In the U.S.A. Custom Inductors

At Altran, we’re a custom inductor manufacturer with over 40 years of experience. We operate out of our CSA, UL, and CE-certified manufacturing facility in Crystal Lake, Illinois. This centralized production ensures strict process control and complete material traceability. In-house quality control guarantees each component meets all design specifications and operational requirements.

Our domestic production also eliminates international shipping delays and reduces supply chain vulnerabilities. Direct communication between our engineering and manufacturing teams enables rapid design modifications and faster prototype turnaround. Local sourcing of materials and components supports quicker response times for urgent orders and design changes.

What Are Inductors?

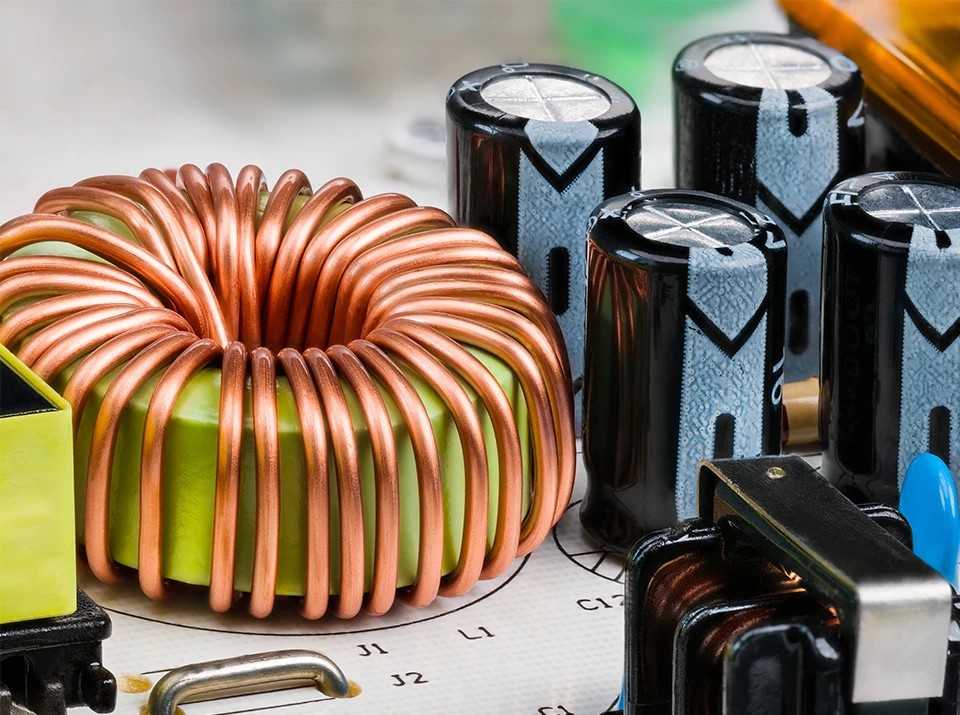

An inductor is a passive electrical component that stores energy in a magnetic field when current flows through it. This two-terminal device consists of insulated wire wound into a coil around a magnetic core made from materials such as iron, ferrite, or iron powder. Changes in current flow create voltage according to Faraday’s Law, with inductance measured in Henry (H) units.

Inductors store energy temporarily for power conversion applications and filter signals when paired with capacitors to form LC circuits. They also allow direct current to pass while blocking alternating current, making them essential for electromagnetic compatibility control and switch-mode power supplies. While transformers transfer energy between separate circuits through electromagnetic coupling, inductors focus on managing magnetic energy within individual circuits for voltage regulation and noise reduction.

Industries and Customers We Serve

Altran manufactures custom inductors for a wide range of applications across many different industries, including:

- Audio and Professional Sound Equipment: Recording studios, concert venues, and high-fidelity home systems rely on our precision inductors for crossover networks, equalizers, and amplifier circuits.

- Automotive (EV and Traditional): Electric vehicles and conventional automobiles integrate our components into charging systems, motor drives, battery management units, and power steering assemblies.

- Networks and Telecommunications: Data centers, cellular towers, and broadband infrastructure depend on our high-frequency inductors for signal conditioning, noise filtering, and power regulation circuits.

- Industrial Power Systems: Manufacturing plants, renewable energy installations, and grid infrastructure utilize our heavy-duty inductors in motor drives, inverters, and power conversion equipment.

- Aerospace and Military Electronics: Defense contractors and aviation manufacturers incorporate our ruggedized inductors into radar systems, navigation equipment, and communication devices built for extreme environments.

- Medical Devices: Hospitals and clinics use equipment containing our low-noise inductors in MRI machines, patient monitors, surgical instruments, and diagnostic imaging systems.

- Research and Development Projects: Universities, laboratories, and technology companies prototype new applications using our custom-designed inductors for experimental circuits and proof-of-concept designs.

Research & Development Inductor Capabilities

Our engineering team designs and builds precision inductors tailored to meet your electrical, mechanical, and thermal specifications. We support both low and high-frequency designs, and focus on consistent quality, tight tolerances, and durability under demanding conditions.

Supported inductor types:

- Power Inductors (Core and Coreless)

- Common Mode Chokes

- High-Frequency Inductors

- Audio Equalization Inductors

- Custom Low-Noise Inductors

Core and construction options:

- Ferrite, Powdered Iron, and Laminated Cores

- Toroidal and Rod Core Inductors

- Gapped Core Designs

- Epoxy-Potted Units

- Hand or Machine Wound (Round, Foil, Litz, Wire Only)

- Any Geometry off the shelf or custom geometry available

Custom-Only Solutions

Altran custom-engineers all of our inductors to meet your exact requirements. Whether your design needs tight inductance tolerances, compact form factor, or high thermal stability, we build each part to spec.

As such, we do not stock standard units. Every unit is custom-designed and manufactured in-house. This approach allows us to tailor solutions for your performance, size, and cost targets.

How to Specify a Custom Inductor

When specifying an inductor, you need to define both its electrical requirements and its physical constraints. Start by stating the target inductance value (in µH or mH) and the acceptable tolerance. Next, define the maximum current it must handle, separating DC bias current (which causes inductance drop) from ripple/AC current (which drives copper and core losses).

Include the operating frequency range, since this determines the choice of core material and geometry. From the application, identify the required saturation current (based on the core’s Bsat) and allowable core losses, usually given in mW/cm³ at a specified flux density swing and frequency.

Specify the core material type (e.g., ferrite, powdered iron, nanocrystalline) with permeability, Curie temperature, and loss characteristics appropriate to the frequency band. Mechanical details such as form factor, footprint, height limits, mounting style (through-hole or surface-mount), and insulation requirements must also be noted.

Finally, add environmental constraints like operating temperature, thermal rise, safety isolation (if applicable), and regulatory standards (UL, IEC). Together, these parameters ensure the inductor can be correctly designed or sourced for reliable performance in its intended circuit.

High-Quality Customized Inductors From Altran

Altran has over 40 years of experience designing and building custom inductors for demanding power electronics applications. Our team combines practical know-how with modern design tools to deliver repeatable and reliable inductors. From prototyping to production, we support our customers with fast turnaround and personalized support.

Click below to learn more and get a quote. quote.