Customized High Frequency Transformers Manufacturer

Altran manufactures customized high-frequency transformers designed for superior performance in challenging environments. These units provide reliable power where standard models fall short of application needs. Each unit is built at our CSA, UL, & CE-certified Crystal Lake, Illinois, facility. From prototype development to full-scale production, we partner with engineers to create custom designs that meet exact specifications.

Our High-Frequency Transformer Capabilities

We specialize exclusively in custom-designed high-frequency transformers. All of our products are 100% purpose-built—tailored from the ground up for specific electrical, mechanical, and environmental requirements.

Our capabilities include a wide array of core geometries and coil constructions, such as:

- E-Core and EC-Core

- Pot Core

- Toroidal

- Air-Core Coils

- Fully Custom Geometries (designed and built in-house)

Whether you need a single prototype or ongoing production volumes, our vertically integrated manufacturing approach provides flexibility in batch sizes and delivery schedules. Our engineering team collaborates closely with customers during the design phase to ensure optimal performance, thermal management, and manufacturability. This collaborative approach results in transformers that meet technical specifications and integrate seamlessly into your final application or product.

If you can imagine it, we can likely build it.

Durable American High Frequency Transformers

All Altran high-frequency transformers are custom-designed and manufactured entirely at our Crystal Lake, Illinois, facility. Our solutions are the result of over 40 years of hands-on R&D and transformer design experience. Each build is backed by decades of engineering insight, precision craftsmanship, and a commitment to performance and reliability.

We utilize advanced manufacturing capabilities and stringent quality control processes to maintain certification readiness for ISO 9001, UL, and RoHS standards. This domestic approach provides reliable sourcing, responsive engineering support, and competitive lead times without overseas supply chain complications.

Our custom transformers are built using premium materials and proven construction techniques that withstand demanding operating conditions. Advanced core materials, precision winding techniques, and robust insulation systems work together to deliver reliable performance over extended service life. Each unit undergoes comprehensive testing to ensure it meets our exacting performance specifications before shipment.

What Are High Frequency Transformers?

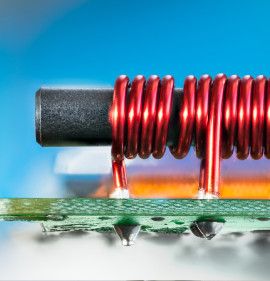

High-frequency transformers are electrical devices that change voltage levels, just like regular transformers. However, they are designed to work with electrical currents that switch direction very quickly. This high-speed operation is what “high frequency” refers to.

Operating at elevated frequencies allows these transformers to be much smaller and lighter than traditional units running at standard frequencies. This makes them ideal for use in compact electronic devices. They also offer improved efficiency in many power conversion applications.

How Do They Work?

High-frequency transformers operate using two or more coils of wire wrapped around a special magnetic core material. When a high-frequency alternating current flows through the input coil, it creates a rapidly changing magnetic field in the core. This changing magnetic field then induces a voltage and current in the output coil. The ratio of wire turns between the coils determines whether the output voltage is higher or lower than the input voltage.

EMI/EMC Design Principles

High-frequency transformers generate electromagnetic interference that can disrupt nearby electronic circuits and violate regulatory compliance standards. Managing electromagnetic emissions becomes increasingly complex as operating frequencies rise and electronic devices become more densely packed. This challenge affects transformer performance and system reliability across various applications.

Electromagnetic compatibility requires careful attention to conductor placement, grounding schemes, and magnetic field containment within transformer assemblies. Strategic winding arrangements and core geometry selection help reduce common-mode currents that typically generate unwanted emissions. Proper shielding techniques and layout optimization prevent interference from reaching sensitive components while maintaining optimal electrical performance.

Proven Performance in Demanding Industries

Our engineering capabilities extend beyond medical imaging to serve a diverse range of critical sectors. We design and custom-build high-frequency transformer solutions for a wide range of industries, including:

- Renewable Energy Systems

- Research & Development

- Telecommunications & Networking

- Industrial Automation

- Defense & Aerospace

- Test & Measurement Equipment

- Power Electronics & Power Supplies

Altran High Frequency Transformers

Altran excels in producing custom-engineered high-frequency transformers for low-to-mid volume needs, each tailored to your specific application. Our advanced capabilities in thermal management, EMI shielding, and protective encapsulation ensure optimal performance and long-term reliability.